About the HACCP World

Electrolux Professional and Total Equipment Suppliers have come together to provide information about HACCP. HACCP is a safety management system created for the food industry that is relevant to laundry operations, as contaminated clothing or garments can negatively impact food production and people’s health. This is why the implementation of HACCP procedures in the laundry is important In the Food industry. Clean uniforms or work clothes are key to keeping a number of critical points under control, and if laundry operations cannot guarantee clean and uncontaminated uniforms, there could be hazards.

However, as Danilo Vanegas, Commercial Director of Electrolux Professional Laundry division, tells us, the HACCP certification in laundry equipment is not yet a standard in the Jamaican or Trinidadian food industry, despite its importance. This is why both companies aim to achieve dissemination of this information that can prevent cross-contamination between work clothes and food.

Additionally, it is also essential that the production plants of the food industry know the benefits of taking control of their laundry. Typically, many producers either outsource their washing or leave it to their employees to clean their uniforms at home. Furthermore, choosing the correct washing machine is also important because if it does not meet the correct cleaning standards, then management changes won’t make a difference. Therefore, knowing how to choose the right machine is critical.

At Total Equipment Suppliers, our president Tracey Umansky, recommends HACCP-certified equipment as this guarantees that the laundry equipment will not be a point of contamination for the work uniforms during the cleaning process. It also allows companies to complete a HACCP “gap” in food handling related to personal hygiene. This opens up international export opportunities to markets in the US and European Union, where HACCP certification is required throughout the food production process.

However, as Danilo Vanegas, Commercial Director of Electrolux Professional Laundry division, tells us, the HACCP certification in laundry equipment is not yet a standard in the Jamaican or Trinidadian food industry, despite its importance. This is why both companies aim to achieve dissemination of this information that can prevent cross-contamination between work clothes and food.

Additionally, it is also essential that the production plants of the food industry know the benefits of taking control of their laundry. Typically, many producers either outsource their washing or leave it to their employees to clean their uniforms at home. Furthermore, choosing the correct washing machine is also important because if it does not meet the correct cleaning standards, then management changes won’t make a difference. Therefore, knowing how to choose the right machine is critical.

At Total Equipment Suppliers, our president Tracey Umansky, recommends HACCP-certified equipment as this guarantees that the laundry equipment will not be a point of contamination for the work uniforms during the cleaning process. It also allows companies to complete a HACCP “gap” in food handling related to personal hygiene. This opens up international export opportunities to markets in the US and European Union, where HACCP certification is required throughout the food production process.

Tracey Umansky

President of Total Equipment Suppliers

Danilo Vanegas (in white)

Commercial Director of Electrolux Professional

Frank Vitale (in black)

Territory Manager, Total Equipment Suppliers

The Evolution of HACCP

- In 1959, NASA wanted to adopt a program to guarantee the safety of food consumed by astronauts in space, and it was the Pillsbury company that introduced this control system to offer these guarantees

- In 1971, the National Conference on Food Protection introduced the HACCP concept to the public.

- In 1972, an outbreak of botulism caused by canned potato soup prompted the US Food and Drug Administration (FDA) to enact regulations with many HACCP concepts. FDA inspectors were trained in HACCP principles and their application. HACCP in other areas of the food industry.

- In 1989, the working group of the National Advisory Committee on Microbiological Criteria for Foods (NACMCF) was formed to establish the guidelines for the application of HACCP in the food industry. Published as “HACCP Principles for Food Production.”

- In 1993, the Codex Alimentarius Commission approved the guidelines for the application of the HACCP system.

- In 2005, the ISO 22000 standard was published, which establishes a Food Safety Management System based on ISO 9001 and the HACCP system.

Clothing As A Source Of Infection

Studies document that MRSA infections can spread through contact with an infected person and with objects such as towels, sheets, and clothing worn by an infected person. Also, the Journal of Clinical Microbiology reports that MRSA can live on fabrics for up to 90 days. Therefore, uniforms, sheets, and towels should be cleaned as part of your disinfection protocol for MRSA-infected spaces.

Studies document that MRSA infections can spread through contact with an infected person and with objects such as towels, sheets, and clothing worn by an infected person. Also, the Journal of Clinical Microbiology reports that MRSA can live on fabrics for up to 90 days. Therefore, uniforms, sheets, and towels should be cleaned as part of your disinfection protocol for MRSA-infected spaces.

-Journal of Clinical Microbiology

Checkpoints

It is essential that food handlers maintain a high level of personal hygiene and cleanliness to avoid transferring harmful bacteria to food. There are a number of guidelines that should be followed to achieve these goals:

- Work clothes must be exclusive for handling food.

- They must be washed daily and be clean at the beginning of each shift.

- They should not be used outside of preparation or production areas.

- They should not have pockets at the waist or buttons.

Electrolux Professional as a Solution

Electrolux Professional has implemented HACCP for their equipment since 1988. This was due to the lack of solutions for the food industry that were automatable and supported.

The criteria they took into account include:

- Equipment Material

- Toxicity

- Pollution Risks

- Ease of Cleaning

- Operating Instructions

- Consequence of Errors

- Process Control and Product Management

- Claims

- Packaging and Instructions

- Contribution to Food Care

Benefits

By taking advantage of HACCP-certified laundry equipment, you will gain many benefits for your business. Some of these include:

- Total control of your uniforms and better-quality control over your cleaning processes.

- Global recognition and access to new markets within the supply chain, thanks to cleaning uniforms within the production plant.

- Controlled costs and recovery of investment in the short-term and long-term savings.

- With industrial laundry equipment from Electrolux Professional, you can use the HACCP International Equipment Certification as a guarantee of food safety for the cleanliness of your workers’ uniforms.

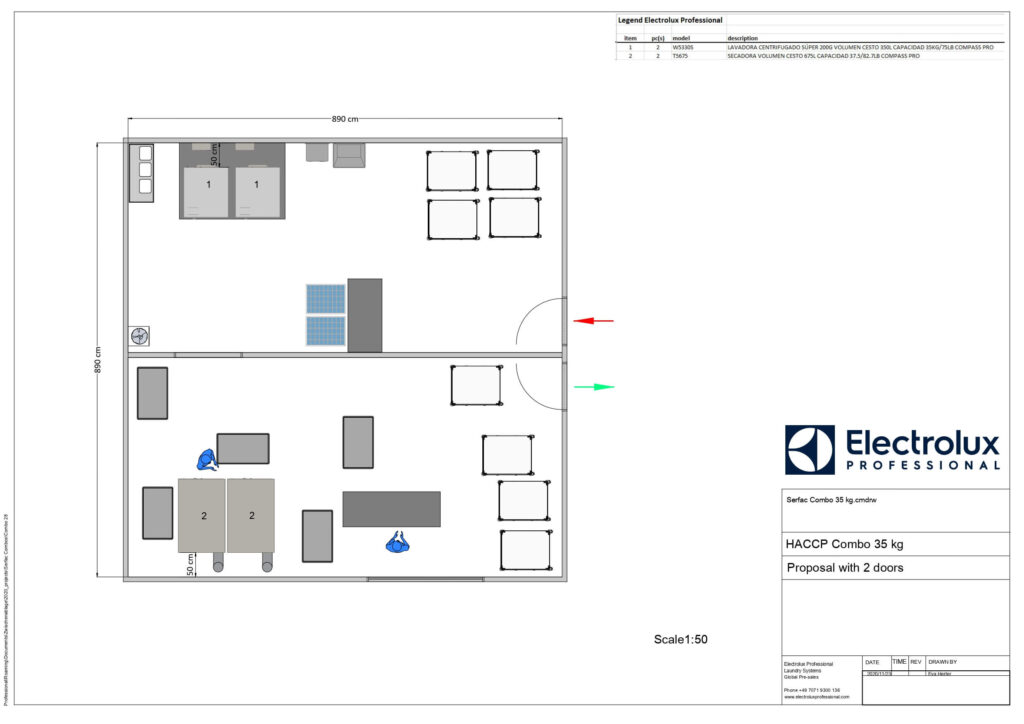

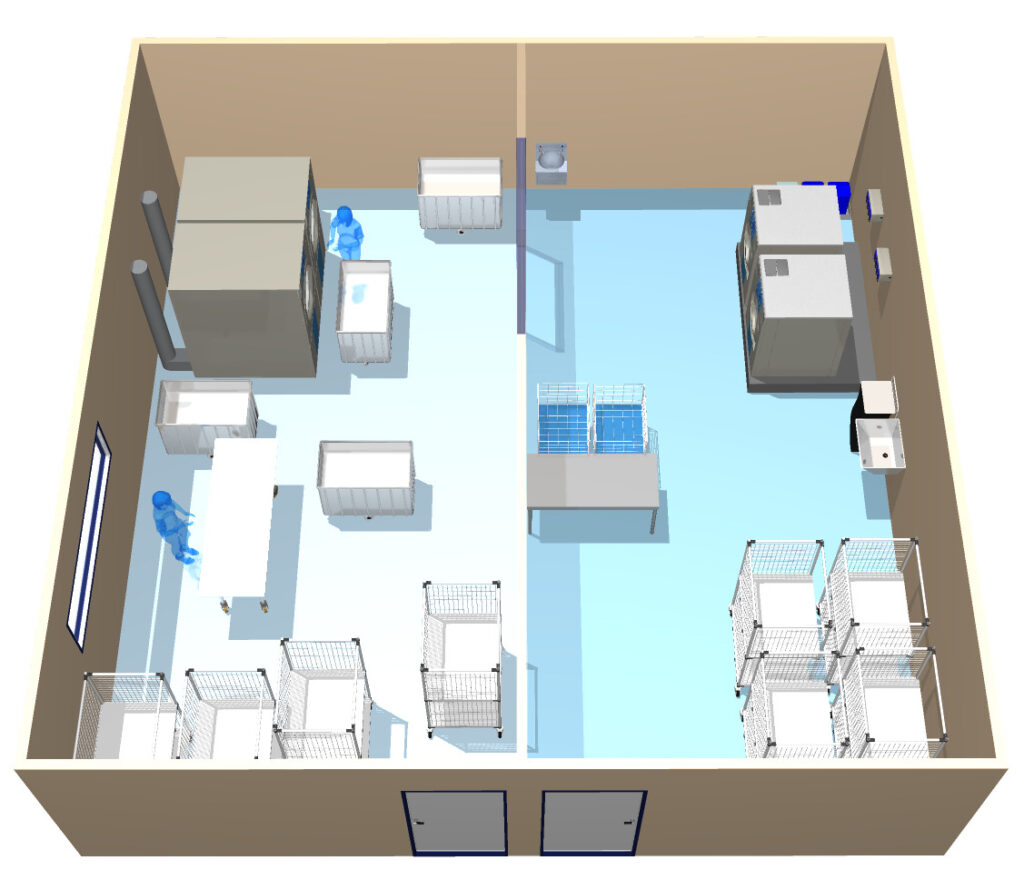

Plans and Equipment Distribution

When Implementing a HACCP laundry solution, it is important to develop a plan. This can help determine the ideal combination of equipment you need to fully process your employees’ work uniforms, aprons, masks, and other fabrics. Additionally, we will help create 2D and 3D plans for your laundry facility to verify the ideal distribution of machines.